How much stock does your business carry? Do your employees spend hours each week unloading truckloads of new products?

If so, your business needs to invest in forklifts. Forklifts offer incredible benefits to anyone that needs to load or unload large amounts of cargo on a regular basis.

You might be thinking that your store doesn’t warrant a forklift. If you’re a small brick and mortar store, a forklift may not have occurred to you; many people associate forklifts with factories and warehouses.

There’s a forklift that’s perfect for individual stores, however. It’s called a Moffett truck mounted forklift.

Truck-mounted forklifts are small, lightweight forklifts that are just right for stores that need a faster unloading solution. They can be mounted to a Moffett truck–a trailer with a mounting point on the back.

There are many advantages to using a Moffett truck and forklift. Not convinced? Keep reading to see how a Moffett forklift can revolutionize your business.

1. Save Time

A semi-truck’s trailer can hold up to 34,000 pounds of goods. That is a lot of product to load up–and everything that goes on the truck is going to need to come off of it. Loading and unloading can both be lengthy processes.

It’s only going to take longer if your workers have to unload everything by hand.

There are a few reasons for this. The most obvious is that climbing onto the truck, picking something up, and carrying it where it needs to go is inherently a slow process; obviously a vehicle is going to speed things up.

The real issue, though, is that the work is so taxing. Even if your employees are making good time at first, they’ll slow down as the unloading process wears them out.

If they’re able to unload the truck with a truck-mounted forklift, they won’t have to endure the same physical labor. That means they can keep a steady pace throughout the process, saving time (and, as a result, money).

2. A Safe Option

Inefficient use of time isn’t the only danger when it comes to unloading trucks. Injuries can result from improper unloading methods. It’s important to follow safety protocols regardless of how you’re unloading a truck.

Even if you’re following safety guidelines, there’s potential for injury. Often, the products in need of unloading will be heavy, which can lead to back issues and other strain.

If an employee drops something they’re carrying, they might damage the product or injure themselves.

All of these issues can be avoided with the use of a truck-mounted forklift. Forklifts do all the heavy lifting for your workers, meaning there’s no chance they’ll hurt themselves trying to lift something heavy.

Moffett forklifts are small and lightweight, so there’s little danger that anyone will be injured (or cause an injury) while using one. The odds of this are even lower thanks to the training a forklift operator undergoes.

3. Highly Maneuverable

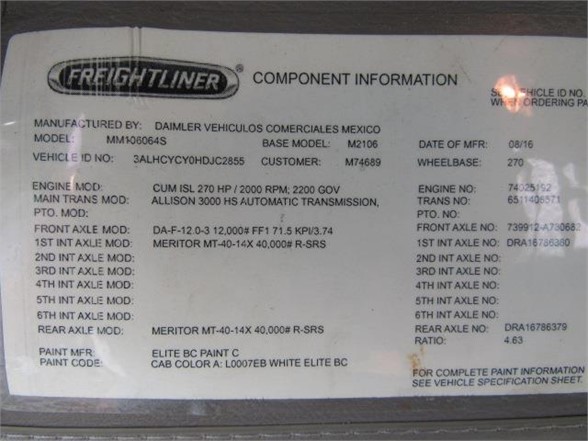

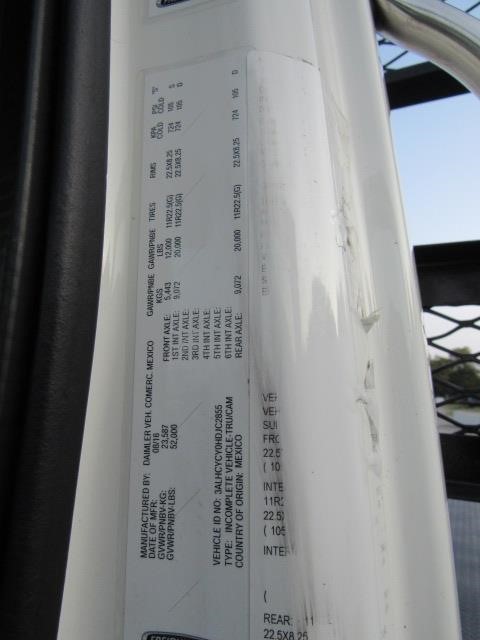

There are a wide variety of quality Moffett trucks available. The trucks themselves are as easy to operate as any comparable truck; the forklifts are lightweight enough that they don’t negatively impact mounted trucks.

Moffett forklifts are also maneuverable. They have a small frame and are much more compact and lighter than an average forklift; as a result, they can move through tighter spaces with ease.

This makes them a perfect choice for retail stores. A large forklift may have trouble working its way around a smaller space, but a Moffett forklift is able to navigate more narrow corridors or take sharper corners.

As an added benefit, Moffett forklifts can operate on less stable ground than many of their larger counterparts. Uneven terrain poses no problem for a Moffett.

This is another boon for smaller businesses that may not have a traditional loading dock. If you need to park your truck in a gravel lot, for example, a Moffett will still be able to assist in unloading.

4. Transportation Is Simple

As noted above, there’s not much difference between a Moffett truck and any other truck in terms of drivability. The only real difference between a Moffett truck and another truck is the presence of the mounted forklift.

As a result, there’s no additional training or other hoops to jump through to drive a Moffett truck–the requirements are the same as any other commercial truck.

As for the Moffett forklift, the simplicity of transport is one of the main selling points. All you need to do is mount the Moffett to the back of the truck and you can take it anywhere it needs to go.

The mounting process is simple, but it adds a huge amount of utility to the forklift. You can use the forklift to load a truck in one area, then mount it and drive somewhere else to unload with the same forklift.

The Moffett forklift is easy to move around your job site, too, thanks to the maneuverability discussed above.

5. Versatile and Easy to Use

Moffett trucks are a great way to transport items for your store. The mounted forklift is ideal for loading or unloading, and the truck itself has a sturdy, reliable trailer.

Moffett forklifts can be used in a huge number of situations. No matter the size of your unloading zone, no matter the terrain you’re working on, a Moffett forklift can get the job done.

They’re no more complicated than an average forklift, either. Training is simple and fast, allowing your employees to get their licenses in a snap. Moffett forklifts are a comfortable, easy option for any forklift operator.

Moffett truck maintenance is simple and consists of the same basic maintenance as any other truck.

Moffett forklifts also require maintenance, which should be trusted to professionals that can service the machines properly.

Improve Your Business With a Moffett Truck

A Moffett truck offers everything you need: a reliable truck with an invaluable forklift attached. Introducing a Moffett truck to your business will increase productivity and cut down on workplace injuries.

Best of all, they are affordable and easy to use. Contact us today for more information about Moffett trucks!